E-Mail: [email protected]

Tel: 13567723322

E-Mail: [email protected]

Tel: 13567723322

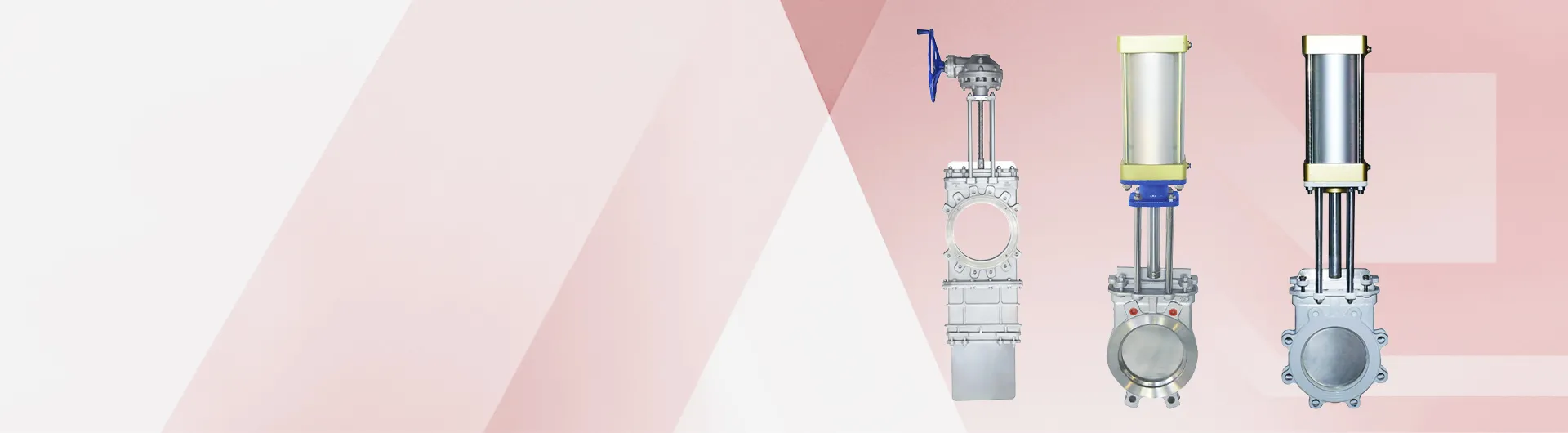

Adapting to Complex Working Conditions, Offering Flexible and Diverse Products

Position: Index>Products>Slide Gate Valve Series>Pneumatic Slide Gate Valve > Pneumatic flapper valve

Widely used in chemical, coal, sugar, sewage, paper and other fields, is an ideal sealing valve. It is especially suitable for adjustment and throttling on pipelines in the paper industry.

Widely used in chemical, coal, sugar, sewage, paper and other fields, is an ideal sealing valve. It is especially suitable for adjustment and throttling on pipelines in the paper industry.

One PZ673X pneumatic plug-in valve main parts and materials:

Valve body, upper cap | Carbon steel, stainless steel |

Valve plate | stainless steel |

Stem | stainless steel |

Seal ring | Rubber, PTFE, stainless steel,hard alloy |

Two PZ673X pneumatic plug-in valve main performance specifications:

Nominal pressure | PN |

Casing test | 1.5XPN |

Leak test | 1.1XPN |

Operating temperature | Rubber 80℃, PTFE≤180℃, hard sealing ≤425℃ |

Working medium | Syrup, paper pulp, sewage, coal slurry, dust, slag-water mix |

Three PZ673X pneumatic plug-in valve implementation standards;

Design and manufacture: JB/T8691-1998

structural length: GB/T15188.2-94

Flange connection: GB/T9113.1-2000 JB/T79-94

testing and acceptance: GB/T13927-92

Four PZ673X pneumatic plug-in valve valve optional drive device model configuration table:

Optional accessories for pneumatic actuators:

1. Single or double control solenoid valve (24V, 220V and other voltages are available for selection, if necessary, an explosion-proof solenoid valve can be selected).

2. Proximity switch.

3. Air source treatment triples (including pressure reducing valve, filter, lubricator).

4. Electric/pneumatic valve positioner (for adjustment type).

1. The cylinder is a device that uses compressed air as a medium to convert its energy into mechanical energy to realize linear motion. It is an executive component widely used in various pneumatic systems and a basic component for industrial automation.

Valve size DN | Cylinder Specifications(Bore size × stroke) | Valve size DN | Cylinder Specifications(Bore stroke) |

50 | Φ65×50 | 200 | Φ160×200 |

65 | Φ65×65 | 250 | Φ200×250 |

80 | Φ80×80 | 300 | Φ200×250 |

100 | Φ100×100 | 350 | Φ220×350 |

125 | Φ125×125 | 400 | Φ250×400 |

150 | Φ125×150 |

2. Technical parameters

cylinder inner diameter(mm) | Φ40 | Φ50 | Φ63 | Φ80 | Φ100 | Φ125 | Φ160 | Φ200 | Φ250 | |

Theoretical piston force(N)(Subject to the working pressure of 0.4MPa | thrust | 490 | 760 | 1215 | 1960 | 3077 | 4800 | 7869 | 12308 | 19227 |

pull | 410 | 680 | 1030 | 1770 | 2675 | 4400 | 7379 | 10035 | 18463 | |

working medium | Purified compressed air containing oil mist | |||||||||

Working pressure (MPa) | 0.15-1 | |||||||||

Ambient temperature (℃) | -10-+80 | |||||||||

Relative humidity | 95 | |||||||||

Piston movement speed (mm/g) | 50-500 | |||||||||

Durability (KM) | 600 | |||||||||

3. Selection range of cylinder stroke

氣缸內(nèi)徑 | Φ40 | Φ50 | Φ63 | Φ80 | Φ100 | Φ125 | Φ160 | Φ200 | Φ250 |

行程選用范圍 | 400 | 500 | 800 | 800 | 1500 | 1500 | 2000 | 2000 | 2500 |

4. Precautions for the correct use of the cylinder:

(1) The movement direction of the load must be consistent with the movement direction of the piston rod to prevent the piston rod from being twisted.

(2) Use the combination of filter, pressure reducer and lubricator (F-R-E combination) to adjust the air quality and increase the service life.

(3) Select a cylinder with a larger output than the actual load to avoid danger when the air pressure is insufficient.

(4) Pay attention to the operating environment temperature. The operating temperature of the piston ring and sealing material in the cylinder is generally limited to within -5℃—+60℃.

(5) In a corrosive gas environment, the material of the piston and sealing part in the cylinder is generally PTFE.

Contact Us

Tel: 0577-67962833

Sales: 0577-67371666

Address: Wuxing Industrial Zone, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

E-mail: [email protected]