E-Mail: [email protected]

Tel: 13567723322

E-Mail: [email protected]

Tel: 13567723322

Providing Professional Industry Information on Knife Gate Valves, Pneumatic Knife Gate Valves, Slurry Valves, Slide Gate Valves, and Ceramic Valves

Position: Index>News > Structure, working principle, precautions and selection method of plug-in valve

slide gate valveIt is a linear motion cutting device that uses the lifting and lowering motion of the plug board to control the cutting of pipeline media. It is widely used in the industrial field, especially in the protection system of oil and gas transmission pipelines, mainly due to its characteristics of fast cut-off, large flow rate, and rapid response. This article will introduce the structure, working principle, usage precautions, and selection method of plug-in valves to users.

Structure of plug-in valve

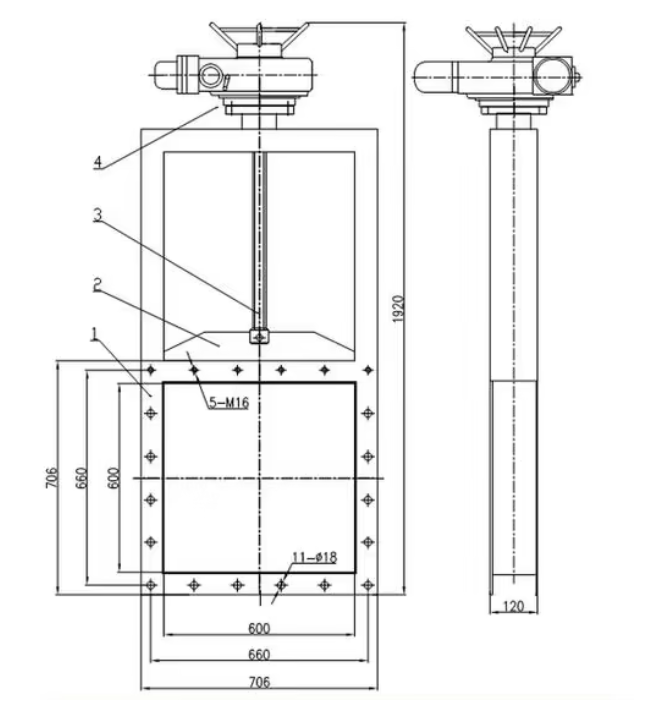

The plug valve is mainly composed of a valve body, a valve seat, a plug plate, and a sealing mechanism. The valve body is equipped with guide rails, and the insert plate slides up and down inside the guide rails, while the sealing is achieved by using elastic plug rings. As shown in the following figure:

Working principle of plug valve

The working principle of the plug valve is to use the plug to cut off the channel of the medium and achieve closure by forming suction through pressure difference. When the plug board is raised, the medium can flow freely; When the insertion plate descends, the medium is cut off, and the pressure difference makes the insertion plate and valve seat tightly fit, forming a seal.

Precautions for using plug-in valves

When using a plug-in valve, the following points should be noted:

1. Check the sealing condition: Regularly check the sealing condition of the valve and replace the plug ring if necessary. The sealing ring is a key component to ensure sealing performance. If damaged or aged, it can cause air or liquid leakage.

2. Lubrication and maintenance: Regularly lubricate and maintain the insert plate and guide rail to ensure flexible movement of the insert plate. Lubricants should be of a type suitable for the medium and temperature, and should be replaced or replenished regularly.

3. Pipeline pressure fluctuation: Pipeline pressure fluctuation should not be too large, otherwise it will shorten the service life of the plug valve. Excessive pressure fluctuations can cause impact or wear between the insert plate and the valve seat, affecting the sealing effect.

4. Prevent foreign objects from entering: Prevent foreign objects from entering the interior of pipelines or valves, causing jamming or damage. Foreign objects can hinder the normal movement of the plug or scratch the sealing surface, and the interior of the pipeline or valve should be cleaned regularly.

Selection method of plug valve

When selecting a plug valve, it is necessary to choose the appropriate plug valve model based on factors such as pipeline diameter, pressure range, and flow requirements. Generally speaking, the following points can be used as references:

1. Plug in valves are suitable for large-diameter, high-pressure, and high flow pipeline systems. If the diameter is less than 50mm or the pressure is lower than 1.6MPa, other types of cutting devices can be considered.

2. Plug in valves are suitable for handling media containing solid particles, but are not suitable for handling viscous or highly corrosive media. If the medium has special properties, corresponding materials and sealing methods should be selected.

3. Plug in valves are suitable for situations where high cut-off time is required. If the cutting time is not a critical factor, other types of cutting devices can be considered.

The above is an introduction to the structure, working principle, usage precautions, and selection method of plug-in valves. Plug in valves play an important role in industrial applications, and proper use and selection can improve the safety and stability of pipeline systems.

2022.01

Wear-resistant ceramic knife gate valve is a valve product with excellent performance. All contact surfaces between it and the medium are ma...

2025.11

With the development of wear-resistant technology and engineering ceramic materials, ceramicsKnife type gate valveThe application in industr...

2021.10

Ceramic valves have gradually become popular in the market in recent years, but there are still many consumers who do not trust this type o...

Contact Us

Tel: 0577-67962833

Sales: 0577-67371666

Address: Wuxing Industrial Zone, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

E-mail: [email protected]