E-Mail: [email protected]

Tel: 13567723322

E-Mail: [email protected]

Tel: 13567723322

Adapting to Complex Working Conditions, Offering Flexible and Diverse Products

Position: Index>Products>Knife Gate Valve Series>Bevel Gear Knife Gate Valve > Bevel Gear Plum Knife Gate Valve

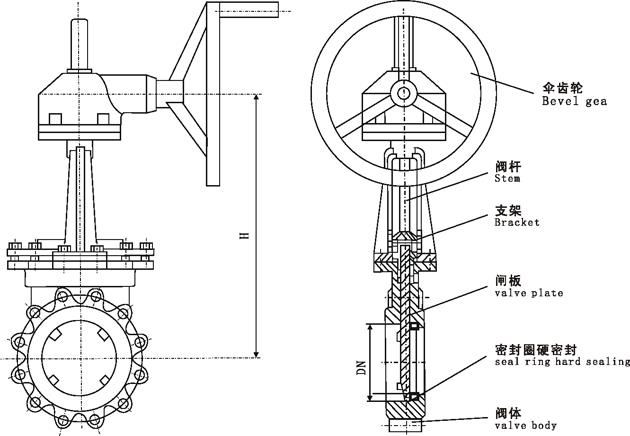

The opening and closing part of the knife gate valve is the gate, and the movement direction of the gate is perpendicular to the direction of the fluid. The manual knife gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valve form a wedge shape. The wedge angle varies with the valve parameters, usually 50. The gate of the wedge type knife gate valve can be made into a whole, called rigid gate

product description

1. Overview of PZ573H bevel gear drive knife gate valve:

1. Nominal pressure: 0.6MPa, 1.0MPa, 1.6MPa, 2.5MPa, 150Lb

2. Nominal diameter: DN50~500mm NPS 2"~20"

3. Applicable temperature: -38~+200℃ (the specific temperature range depends on the material of the sealing pair and the properties of the medium) 4. Connecting flange: ANSI B16.5, GB/T9113, JB/T79, HG, SH, JIS, DIN , NF, BS

5. Main material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8, CF8M, CF3, CF3M

6. Seal type: hard seal, soft seal

7. Leakage: Hard seal: Class D (liquid 0.1×DN mm3/s) Soft seal: Class A (zero leakage)

8. Matching accessories: mounting flange

2. Features of PZ573H bevel gear drive knife gate valve:

1. It adopts a full-circle channel design, and the bottom end of the blade is machined into a blade, which has a high finish and ensures good sealing.

2. Teflon and mud scraper are installed on the top of the cutter board, which can prevent abrasive substances such as dust and gravel from entering the stuffing box.

3. The wear-resistant hemming cone made of polyester grease or Ni-containing wear-resistant cast iron is installed at the inlet end of the knife gate valve, which can prevent the particulate material from directly scouring the seal, thereby improving the working conditions and prolonging the life.

4. According to the needs, multiple flushing ports can be set around the valve body, which can be directly flushed with air, steam or water to prevent the accumulation of sediments, which is especially suitable for fluids that are difficult to input.

5. The bevel gear wafer type knife gate valve has a compact design, small footprint, light weight, easy installation, perfect wear-resistant and anti-blocking measures, easy maintenance and long service life. It can widely meet the requirements of papermaking, pulp industry, industrial sewage and municipal sewage treatment, chemical plant, fly ash treatment, bulk material transportation, food and beverage industry and harsh environmental conditions.

The opening and closing part of the knife gate valve is the gate, and the movement direction of the gate is perpendicular to the direction of the fluid. The manual knife gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valve form a wedge shape. The wedge angle varies with the valve parameters, usually 50. The gate of the wedge type knife gate valve can be made into a whole, called Rigid gate; it can also be made into a gate that can produce a small amount of deformation to improve its craftsmanship and make up for the deviation of the sealing surface angle during processing. This gate is called an elastic gate. When the knife gate valve is closed, the sealing surface It can only rely on the medium pressure to seal, that is, relying on the medium pressure to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing. Most knife gate valves are forced to seal, that is When the valve is closed, it is necessary to rely on external force to force the gate to the valve seat to ensure the tightness of the sealing surface. This type of valve should generally be installed horizontally in the pipeline.

1. Main shape and connection size (mm)

MPa | DN | L | D1 | D2 | H | n-M | MPa | DN | L | D1 | D2 | H | n-M |

0.6 | 50 | 43 | 90 | 110 | 475 | 4-M12 | 1.0 | 50 | 43 | 100 | 125 | 475 | 4-M16 |

65 | 46 | 110 | 130 | 500 | 4-M12 | 65 | 46 | 120 | 145 | 500 | 4-M16 | ||

80 | 46 | 125 | 150 | 535 | 4-M16 | 80 | 46 | 135 | 160 | 535 | 4-M16 | ||

100 | 52 | 145 | 170 | 605 | 4-M16 | 100 | 52 | 155 | 180 | 605 | 8-M16 | ||

125 | 56 | 175 | 200 | 665 | 8-M16 | 125 | 56 | 185 | 210 | 665 | 8-M16 | ||

150 | 56 | 200 | 225 | 765 | 8-M16 | 150 | 56 | 210 | 240 | 765 | 8-M20 | ||

200 | 60 | 255 | 280 | 880 | 8-M16 | 200 | 60 | 265 | 295 | 880 | 8-M20 | ||

250 | 68 | 310 | 335 | 1020 | 12-M16 | 250 | 68 | 320 | 350 | 1020 | 12-M20 | ||

300 | 78 | 362 | 395 | 1220 | 12-M20 | 300 | 78 | 368 | 400 | 1220 | 12-M20 | ||

350 | 78 | 412 | 445 | 1375 | 12-M20 | 350 | 78 | 428 | 460 | 1375 | 16-M20 | ||

400 | 102 | 462 | 495 | 1560 | 16-M20 | 400 | 102 | 482 | 515 | 1560 | 16-M22 | ||

450 | 114 | 518 | 550 | 1720 | 16-M20 | 450 | 114 | 532 | 565 | 1720 | 20-M22 | ||

500 | 127 | 568 | 600 | 1870 | 16-M20 | 500 | 127 | 585 | 620 | 1870 | 20-M22 | ||

600 | 154 | 670 | 705 | 2220 | 20-M22 | 600 | 154 | 685 | 725 | 2220 | 20-M27 | ||

700 | 165 | 775 | 810 | 2570 | 24-M22 | 700 | 165 | 800 | 840 | 2570 | 24-M27 | ||

800 | 190 | 880 | 920 | 3030 | 24-M27 | 800 | 190 | 898 | 950 | 3030 | 24-M30 | ||

900 | 203 | 980 | 1020 | 3430 | 24-M27 | 900 | 203 | 1005 | 1050 | 3430 | 28-M30 | ||

1000 | 216 | 1080 | 1120 | 3470 | 28-M27 | 1000 | 216 | 1110 | 1160 | 3470 | 28-M30 | ||

1200 | 254 | 1295 | 1340 | 4230 | 32-M30 | 1200 | 254 | 1325 | 1380 | 4230 | 32-M36 |

Contact Us

Tel: 0577-67962833

Sales: 0577-67371666

Address: Wuxing Industrial Zone, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

E-mail: [email protected]